Ultrafiltration Technology

Ultra Filtration

Ultrafiltration Technology: Moving Towards a Cleaner, More Sustainable Future

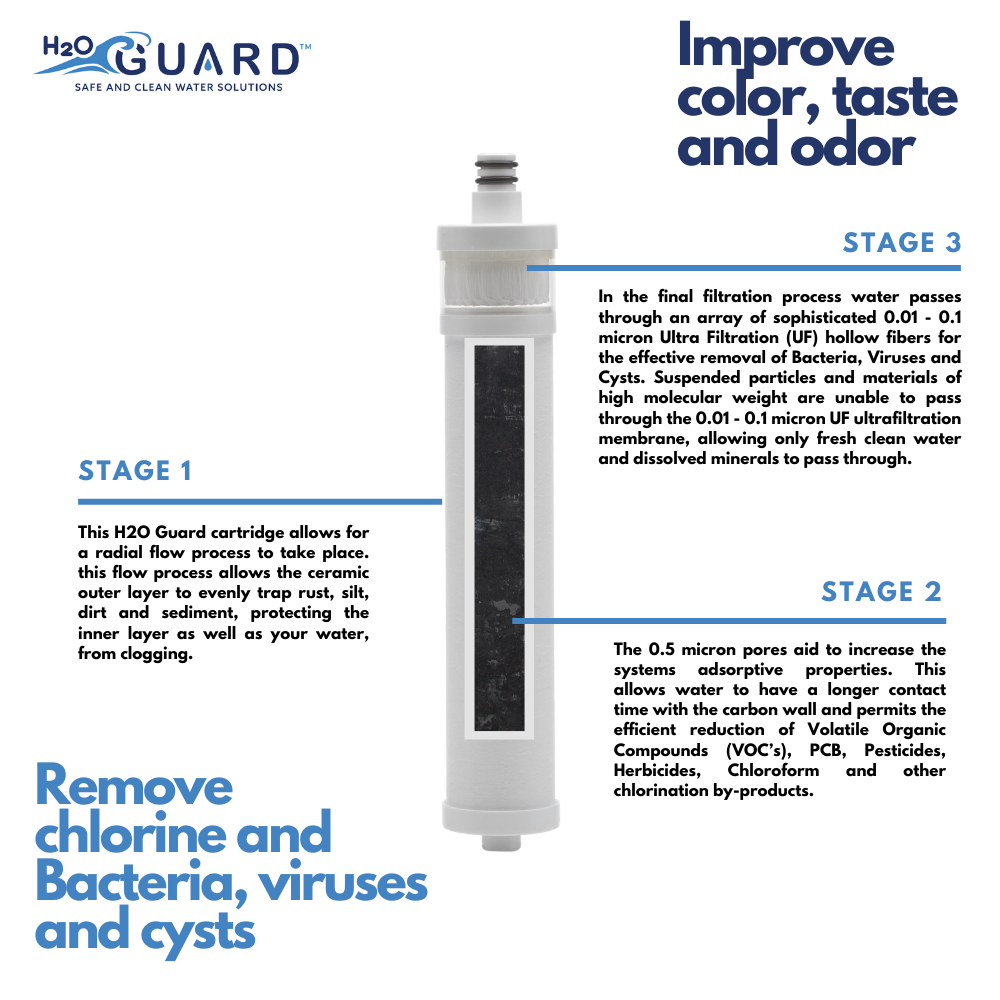

Ultrafiltration (UF) is a membrane filtration technology that has revolutionized the way we treat and purify water and other liquids. This process uses semi-permeable membranes with extremely small pores, typically in the range of 0.01 to 0.1 microns, which allows efficient separation of particles, bacteria, viruses, colloids and macromolecules from fluids. Unlike other filtration methods, ultrafiltration does not require the use of harsh chemicals, making it a more environmentally friendly and sustainable option.

How does Ultrafiltration work?

The ultrafiltration process is based on the application of pressure on a liquid to force it through a semi-permeable membrane. The pores of the membrane are small enough to retain particles and microorganisms, but allow water and dissolved salts to pass through. This results in a clarified and purified liquid, free of impurities that could be harmful to health or industrial processes.

The membranes used in ultrafiltration are designed to be highly resistant and durable, making them ideal for applications where continuous and efficient treatment is required. In addition, these membranes can be cleaned and reused, reducing operating costs and environmental impact.

Improve your water quality today!

Discover the benefits of pure water with our high quality filters.

Advantages of Ultrafiltration

- Efficiency: UF is capable of effectively removing particles and microorganisms, providing a high level of purification.

- Sustainability: By not requiring the use of harsh chemicals, UF is a more environmentally friendly option.

- Cost Savings: The ability to reuse membranes and reduce water and energy consumption contributes to a more economical operation.

- Versatility: Its application in various industries demonstrates its adaptability to different needs and challenges.

Home, Hotels and Restaurants

Electronics and Semiconductors

Purification

Industrial

Filtration in Agriculture

Certified technology

Guaranteed quality

Pre-treatment: The liquid to be treated passes through a coarse filter to remove large solids and protect the membrane from clogging.

2. Pressurization: The liquid is pumped under pressure through the semi-permeable membrane, whose pores (0.01-0.1 microns) retain particles, bacteria, viruses and macromolecules.

3. Filtration: Water and dissolved salts pass through the membrane, while impurities are retained, resulting in a purified liquid.

4. Membrane Cleaning: Periodically, the membrane is cleaned to remove accumulations and maintain its efficiency.

5. Collection and Use: The purified liquid is collected for use, while the retained residues are discarded or treated.

- Elimination of harmful microorganisms: It eliminates bacteria, viruses and parasites that cause diseases such as diarrhea, cholera and hepatitis.

- Safe and clean water: Provides water free of suspended particles and contaminants harmful to human consumption.

- Protection against toxic chemicals: By not using aggressive chemicals, it avoids the presence of harmful residues in the water.

- Disease prevention: Reduces the risk of waterborne diseases, improving public health.

- Water quality in homes and hospitals: Ensures a supply of purified water, essential for hygiene and health in critical environments.

- Benefits for skin and hair: The ultra-filtered water is free of impurities and chemicals, which helps keep skin hydrated and hair softer and healthier, reducing irritations and problems such as dryness.

- Long-term sustainability and health: Promotes the use of clean technologies, protecting the environment and the health of future generations.

Drinking Water Treatment:

- Purification of water for human consumption, eliminating bacteria, viruses and suspended particles.

- Improved water quality in communities and homes.

Food and Beverage Industry:

- Clarification of juices, wines, beers and other liquids.

- Elimination of microorganisms and particles that affect the flavor, texture and shelf life of products.

- Wastewater Treatment:

- Reuse of wastewater in industrial processes or for irrigation.

- Reducing environmental impact by minimizing the discharge of pollutants

Pharmaceutical Industry:

- Solution purification and protein concentration.

- Separation of specific compounds in drug manufacturing.

- Electronics and Semiconductors:

- Obtaining ultrapure water for electronic component manufacturing processes.

- Prevention of contamination of sensitive products.

Health and Beauty:

- Provides purified water for skin and hair care, preventing irritation and dryness.

- Use in spas and esthetic centers for treatments that require high quality water.

Agriculture and Aquaculture:

- Water treatment for irrigation and hydroponic crops.

- Water purification in aquaculture farms to ensure a healthy environment for fish.

Energy and Petroleum:

- Water treatment in power generation processes.

- Purification of water used in oil extraction and refining.

Hospitals and Laboratories:

- Ultra-pure water supply for medical procedures and clinical analysis.

- Guarantee of contaminant-free water in critical environments.

Homes and Buildings:

- Domestic filtration systems to improve water quality in showers, faucets and appliances.

- Protection of pipelines and equipment by reducing sediment accumulation.

Is ultra-filtered water safe to drink?

Yes, ultra-filtered water is safe for human consumption, as it removes harmful microorganisms and particles, providing clean and purified water.

Does ultra-filtration remove minerals from water?

No, ultrafiltration does not remove dissolved minerals such as calcium or magnesium, as it only retains particles and microorganisms.